Rudder

The rudder is another crucial part of the boat that needs attention. Driving the car with a loose steering wheel, or close manoeuvring without power steering (heavy), this is the same effect as not having your rudder set up correctly. In addition, the fact that the rudder blade itself is as long as it is, just amplifies the potential problem.

We hear many stories where the blade or the stock broke whilst sailing. Usually it happens when the boat has just been launched and the rudder has yet to be locked down due to shallow water. A gust of wind hits, the boat heels over and the rudder is used to steer the boat flat. This loads the rudder up immensely and can cause it to break or at least weaken. Instead of using the rudder to steer, people should be using balance and sails to steer. Come on a training course to find out more.

Anyay back to the topic of this article.

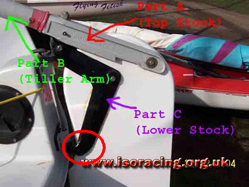

The rudder consists of 4 main components:

|

|

|

| Ensure the label is removed else it gets soggy and falls off no matter what type of adhesive you use (I found this one out the hard way). With the rudder locked down, using a pencil, mark either side of the lower beam of the bottom stock (2 lines on each side of the blade). Unlock the rudder and you should now see where the stock lines up on the blade when down. This is the only area where you need to fit the packing. If you put it in the other areas that are in the stock when the blade is up, you will struggle to get the blade up as it will be too snug a fit. | |